Victoria Ezenachukwu always knew that she had a gift of craftsmanship. Growing up, she exhibited qualities that proved that she would earn with the skills of her hands. But she did not know how to go about it.

For instance, her home economics practical, which was the design of an apron in JSS 3, was picked as the best in the entire school by the external invigilator.

“Although it was hand-sewn, I made it neatly, using needle and thread to stitch my name, school name and other details; mine was the sample representing our school,” she recalled.

In her first year at the Federal University of Technology Owerri (FUTO), Imo State, where she studied crop science and technology, she lost her father and her upkeep money was drastically reduced. Then, she knew that she needed to do something to make money to survive.

She tried out a few businesses until she heard of a training for Ankara shoes and bags. A member of the Campus Charismatic Movement, which she was part of in school, announced that she was willing to train interested students who would have the opportunity to work with her and earn some money.

That marked the beginning of her journey to craftmanship. The year was 2017. Inside her room, the woman trained Ezenachukwu on how to use Ankara to wrap old, worn-out shoes, bags and sandals, and make jewellery from scratch.

But she wanted more. In 2018, she moved back to Lagos, where she spent three months learning how to make only slippers. She spent N60,000. When she returned to school, she opened a mini store in Eziobodo, a nearby village, and was making slides and earning money to cater to her needs. She always travelled to Aba to buy materials for work.

In 2019, Ezenachukwu, who is the seventh in a family of eight, went to learn how to make shoes in Port Harcourt for six months and spent N150,000. Her school was on strike at the time, and she was staying with her eldest brother.

After her graduation from school in 2021, she travelled back to Lagos to enrol in a professional master class. She was not satisfied with what she had learned from Port Harcourt.

“He had old machines and was not doing new styles, and I wanted something else,” she said.

“I had searched for a place to learn in Abuja and Ibadan but did not find what I was looking for.”

Ezenachukwu, who is now 26, spent four months in Lagos and N500,000 to improve on her knowledge. She said her third instructor made the learning process extremely difficult and unbearable.

“He wasn’t willing to share top secrets and was always avoiding questions,” she said.

“He always refused to take us to the market to learn about good materials. I learned a lot of things from YouTube videos and trial and error.”

She added that he would not also teach her and others how to operate the machines because he thought they were expensive and they could not afford them. When she eventually bought her own, he asked her to pay so he could teach her to operate it. She went back to YouTube because she had spent a lot of time there.

She spent one year and four months learning patterning, pattern conversion, coupling, stitching, lasting, filling and final coupling.

EXPORTING LEATHER BUT IMPORTING FOOTWEAR

In its 2019 macro-economic outlook report, the Nigeria Economic Summit Group (NESG) stated that the Nigerian leather industry had been projected to generate over $1 billion by 2025.

Olusegun Omisakin, Head of Research, NESG, was quoted as saying that the leather processing sector also employed over 750,000 workers, with about 500,000 workers in the finished leather goods sector. According to the report, Nigeria has the largest resource of goatskin and kidskin in Africa, representing 46 percent and 18 percent of the total in West Africa and Africa, respectively, with about 61 million units.

“Domestically, the industry represents the second major earner of foreign exchange after oil, with total exports of tanned skins amounting to about $240 million in 2015,” the report said.

With over 50 million animal skins processed annually by tanneries, together with other related activities, the leather industry contributes about 24 percent of the total agriculture GDP in Nigeria.

Sadly, while Nigeria is a net exporter of raw hides and skins, including semi-processed leather, it is also a net importer of finished leather products, with total imports of about $500 million worth of leather products annually.

China, United States, Italy, India and the United Kingdom were the top partner countries from which imports were made in 2021, according to a report by the World Integrated Trade Solution.

Vahyala Kwaga, a senior research and policy analyst at Budgit Foundation, said that the lingering challenges in the industry, such as multiple taxation, insufficient infrastructure, including reliable electricity and transportation networks and a lack of government intervention, affect local production capacity, leading to a revenue loss of about $300 million annually.

“For instance, the market size of the Aba shoe industry is about N144 billion ($350.364 million), but the Aba shoe industry supplies only 0.00128% of the $271.82 billion global shoe market,” he said.

“Also, the lack of technological expertise affects advanced shoemaking and skilled craftsmanship, which are essential for quality footwear.”

THE ETHIOPIAN EXAMPLE

Unlike Nigeria, Ethiopia has emerged as a shoe-making hub for the world with its well-organised and formalised leather industry, attracting Chinese and Turkish firms such as Huajian and My Shoes.

A BusinessDay report showed that Ethiopia’s comparative advantage in shoes stems from a combination of cheap labour and electricity, as well as a formal structure, which shoe makers in Aba, Kano and Lagos, three biggest hubs in Africa’s most populous country, lack.

According to the Ethiopian Investment Commission (EIC), Ethiopia attracted over $500 million in FDI to the shoe and leather industry, with about 124 investors willing to invest $3.5 billion between October and December 2016.

The East African country also exported $33.7 million worth of footwear products mainly to the United States in 2015, one million lower than the preceding year.

READ ALSO: Nigerian Student Sets New Painting Record of 100 Hours

DISCOURAGEMENTS WITHIN AND WITHOUT

Ezenachukwu’s decision to venture into shoemaking did not come without opposition, especially given that she was expected by her family and friends to only focus on her education, get good grades and secure a job after graduation.

First, it was from her mother, whose friends always asked if her daughter was into shoemaking because she could no longer afford to pay her school fees and other bills after her husband died.

“Sometimes, they saw pictures of my shoes and sandals on Facebook and they would ask her if I had dropped out or was still going to school,” she recalled.

“And so she asked me to stop severally, but I continued.”

Back in school, her classmates teased her and said that rather than focus on her education, she was wasting away her parents’ money and learning how to make shoes, which they termed local.

Eventually, she discovered that one of those who criticised her went to learn shoemaking after they graduated from school.

“She said I inspired her to start the training and that she was proud of how confident I am in the craft.”

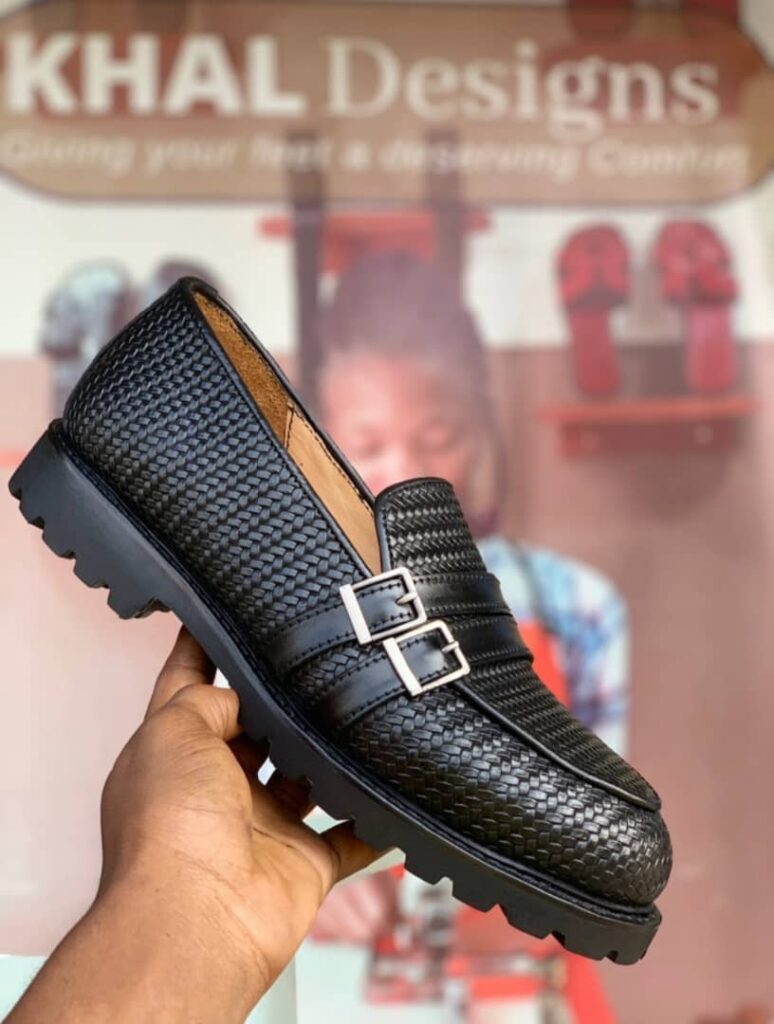

Currently, the lowest leather shoe she sells is N35,000. Some of them go for N70,000. Her sandals cost N15,000, while her Birkenstock wears also sell for N15,000. While she was making only slippers, she charged N50,000 to train for 6 months.

But after the last training in Lagos, she started charging N250,000 for a year package and 100,000 for six-month-only training on slippers Now she charges N300,000 for the full package and N150,000 for slippers, half shoes and belts.

Ezenachukwu has gone on to train other women in shoemaking and has also exported some of her products to different countries, including the US, Canada, Ghana, South Africa, Kenya and the UK.

CHALLENGES

Like every other shoemaker, Ezenachukwu has had to deal with some challenges, including the widespread lack of power supply. She spends between N3,000 and N5,000 daily on fuel. That is about N18,000 weekly and that affects her income. In Ebute Meta, where she owns a store, there is hardly any power supply. Whenever they manage to bring it, it does not last long.

Also, she said that there is widespread unwillingness on the part of young people to learn skills like shoemaking because they want to make quick money.

The rising cost of products on the market has not also helped. Recently, she almost repaid a customer with whom she negotiated for a shoe last year but could not pay until this year.

“When he wanted to send the money this year, he sent the same amount we had agreed; sadly, the price had gone up,” she said.

“I tried to explain the situation to him but he wasn’t having it at all.”

“Prices keep increasing almost on a daily basis and sometimes it discourages people from wanting to make shoes.”

To deal with this, Ezenachukwu now invests in bulk buying. In January, for instance, she bought materials in sheets and drums directly from importers just to bring the price a little lower for her customers.

An economic expert at SBM Intelligence says that the government must look into supporting creatives who have a lot of great ideas but lack the funds to pursue them.

“They must also provide an environment that is conducive enough, such as reduced taxation, improved electricity and road infrastructure, to enable those in the industry to thrive,” he said.

READ ALSO: 9-Year-Old Nigerian Graduates From US High School

HOPES FOR THE FUTURE

Ezenachukwu started on the floor of her room, then grew into a space in school and, now, a store in Lagos. She started her company, Khal Designs, when she finally moved back to Lagos after school in 2022.

She does not have employees yet. She only gets some of those she has trained on a contract basis whenever she gets bulk requests and pays them after the job. So far, she has trained over 15 people.

But she hopes to be able to employ people and reduce the rising unemployment rate. Her jobs are based on demand and recommendations. But she is looking to open a showroom where individuals can walk in to pick up a pair or more, after which she will begin a factory that’ll stand out.

“It is hard to find factories that focus on quality,” she said.

“A lot of factories focus on quantity, but with us, we will try to create a balance by creating quantity while still maintaining our quality.”

WAY OUT FOR THE INDUSTRY

For Kwaga, all hope is not lost for the shoemaking industry in Nigeria.

According to him, with Nigeria’s large human capital, there is a need for investment in human capital development through education and skills training, as well as enhanced investment in education and vocational training.

“By helping to equip citizens with relevant skills, Nigeria can foster a skilled workforce producing quality footwear domestically,” he said, adding that favourable policies can boost domestic manufacturing in Nigeria. He noted that encouragement of private-public investments in footwear manufacturing infrastructure, machinery, and training is of the essence.

Also, Ibukun James, a programme officer at Budgit, said that leveraging manufacturing hubs such as Aba and other clusters would strengthen clusters and improve access to raw materials and market linkages.

“There is a need to review trade policies and import restrictions, and evaluate import restrictions and tariffs on footwear,” he said. “While some protectionist policies exist, a balanced approach is necessary to avoid negatively impacting consumers.”

This, according to him, is in addition to engaging in discussions regarding Nigeria’s participation in AfCFTA and assessing how trade liberalisation can benefit the domestic footwear industry.

“Quality control is important, as local and global standards exist to compete with, and these will raise the necessary awareness about locally-made footwear and promote unique features,” he said.

Now, Ezenachukwu’s mother uses her as a perfect example of determination in church and during discussions with her friends.

Subscribe

Be the first to receive special investigative reports and features in your inbox.